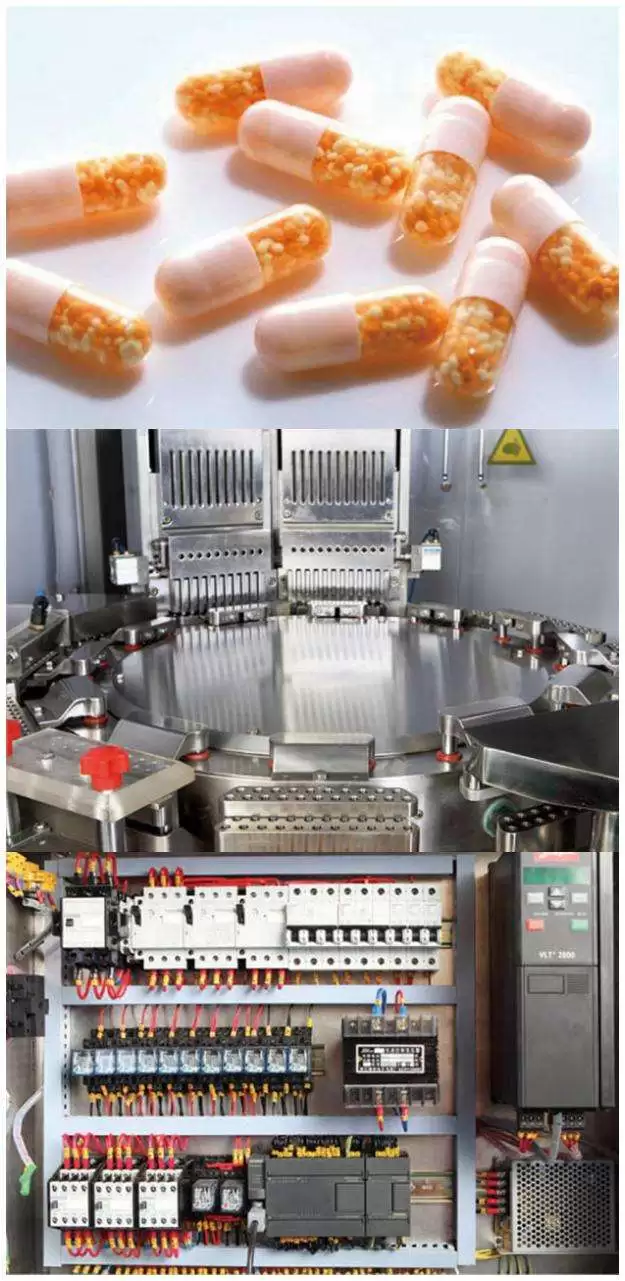

This machine is an intermittent full automatic capsule filling machine with multiple tamping stations, precise design and stable performance. It can completes the following process: feeding capsule, separating capsule, filling, rejecting defective capsule, closing capsule, discharging finished capsule automatically. It adopt closed rotary table with twelve station. There are 21 holes in four rows crossing on the module. Function of machine reach international advanced standard, which also meet the requirement of “GMP” and FDA standard. It’s absolutely the most ideal machine for producing capsule products.

Features

1)Output : 180000capsules /hour

2)Change speed by transducer ,PLC control (C type)

3)Easy to operate and install

4)Function for filling powder,pellet,granule,pellet and pill into capsule.

5)Automatic detection and diagnosis of lack of material, capsule and mechanical trouble, make alarm and stop automatically.

6)Displaying in-time speed and accumulative output.

7)Available for electronic signature and recording, and Industrial Ethernet.

Machine Details Packaging

Machine Detail

Specification

Filling Percentage

/

Productivity

3000 pcs/min

Number of hole

21 holes

Size of Capsule

00~5#

≥99.8%

Dosing Precision

≤±3

Power supply

380V 50HZ

Power

9.5kw

Water supply

500L/H 0.1~0.2Mpa

Dust collector

230m3/H

Compressed air

0.2 m3/min 4~6kg

Noisy

≤70db

Overall dimensions

1235×1218×2025(+250)mm

Weight

2000kg