Usage

The BGB-C Series high-efficiency coating machine is mainly used in pharmaceutical and food industries. It is a high-efficiency, energy saving, safe, clean and mechatronics equipment for coating tablets, pills and candies with organic film,water soluble film, slow and controlled release film and sugar film etc., which conforms to the requirement of GMP.

Features

1.The control system consists of PLC and HMI. The design is reasonable and programming is flexible, which are adapt to the different needs of pharmaceutical technology, thus featuring reliable work, stable performance and conforming to the requirement of GMP.

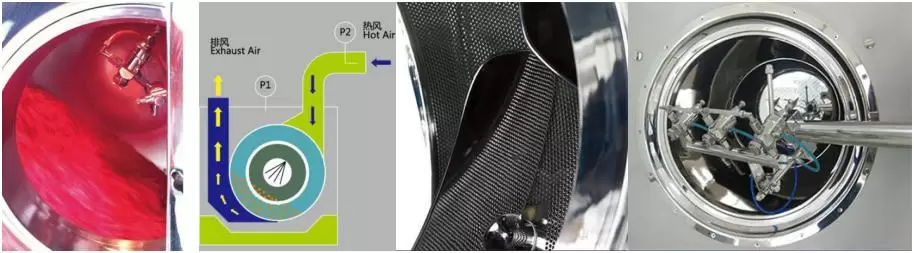

2.Under the action of the agitator of streamline guide plate, the tablet cores are tumbling smoothly and exchanging frequently, thus eliminating the phenomenon of tablet cores falling form a high place and the collide, so that solve the problems of broken pieces and chipped edge, and also improve the rate of finished products. The narrow surface of the guide plate eliminates the adhesion of coating material and improving the quality of medicine.

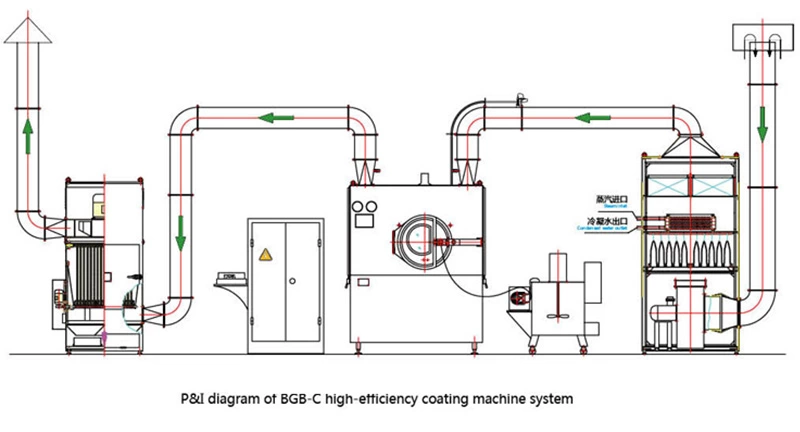

Working Principle

The tablet cores make continuous complicated orbital motion within the closed rotating drum under the action of astreamline guide plate. During the motion,coating medium automatically sprays according to the technological process and rational technological parameters, at the. same time hot air is supplied under a negative pressure. The hot air penetrates through the tablet core layers and is discharged from the bottom of the layers,so that the coating medium sprayed on the surface of tablet cores will dry rapidly and evenly, thus forming a solid and smooth surface film.

1570x1360x

2000

1570x1260x

2000

Overall dimension of main machine(LxWxH)(mm)

1100x850x

1570

Model

BGB-600C

BGB-500C

BGB-450C

BGB-350C

BGB-200C

BGB-150C

Working capacity (Kg/batch based on bulk density of 1)

600

500

450

350

200

150

Speed-adjusting range of coating drum (rpm)

2-10

2-10

2-11

2-11

2-15

2-15

Motor power of main machine (Kw)

5.5

5.5

4.0

4.0

3

2.2

Regulating range of hot air temperature (℃)

Normal temperature-80℃

Filtration accuracy of hot air(μm)

0.5μm(100,000 grade)

Motor power of hot air machine(Kw)

5.5

5.5

2.2

2.2

1.1

1.1

Motor power of exhause machine(Kw)

15

11

7.5

7.5

5.5

5.5

Motor power of vibration dust-cleaning device

0.74

0.74

0.37

0.37

0.37

0.37

Motor power of peristaltic pump(Kw)

0.18

0.18

0.18

0.18

0.18

0.18

Overall dimension of main machine(LxWxH)(mm)

2200x2240x2320

2000x1940x2320

2000x1800x2300

2000x1560x2300

Weight of main machine(Kg)

2500

2300

1800

1650

1000

900

Model

BGB-100C

BGB-75C

BGB-40C

BGB-20C

BGB-10C

BGB-5C

BGB-3C

Working capacity (Kg/batch based on bulk density of 1)

100

75

40

20

10

5

3

Speed-adjusting range of coating drum (rpm)

4-19

4-19

4-19

6-30

6-30

6-30

6-30

Motor power of main machine (Kw)

1.1

1.1

1.1

0.55

0.55

0.55

0.55

Regulating range of hot air temperature (℃)

Normal temperature-80℃

Filtration accuracy of hot air(μm)

0.5μm(100,000 grade)

Motor power of hot air machine(Kw)

1.1

1.1

1.1

0.75

0.75

0.75

0.75

Motor power of exhause machine(Kw)

3

3

3

2.2

2.2

2.2

2.2

Motor power of vibration dust-cleaning device

0.37

0.37

0.37

0.37

0.37

0.37

0.37

Motor power of peristaltic pump(Kw)

0.18

0.18

0.18

0.03

0.03

0.03

0.03

1200x1150x1765

1200x965x1750

1200x880x1715

1100x750x1540

Weight of main machine(Kg)

650

550

500

420

380

380

380