Service Conditions of High-speed Tablet Press

1)Working environment:

The working environment conforms to relevant requirements of GMP specification.

2)Material pressing requirement

2.1 Granule requirement

Granule size range: 12-60 meshes, great compressibility and mobility;

Synthetic medicine starch tablet: the granules should be uniform and not moist; the proportion of fine powder (above 60 meshes) in the granules should not exceed one third; Traditional Chinese medicine granules: pure extract, semi-extract and raw powder granules should not be moist and should have certain mobility.

2.2 Dry powder

It is applicable to direct powder tabletting, and the pressed powder should have certain compressibility and mobility.

3)Tabletting form:

The machine can be used for pressing common round tablets, large tablets, abnormal tablets, special abnormal tablets, single/double-face carved tablets, cartoon tablets, etc.

4)Power supply requirement 380V, 50Hz, three-phase five-wire system, no mutual interference between N line and PE line.

(10,000 tablets/h)

20mm

7.5KW/380V, 50Hz, 3 phase five-wire system

Remark

Model

GZPK26

GZPK32

GZPK40

GZPK50

Punch pin number

26

32

40

50

Punch Type (IPT)

D

B

BB

TF16

Production range

34000~171000

42000~211000

52000~264000

Rotating speed (rmp)

22~110

Maximum main pressure

100KN

Maximum pre-pressure

16KN

Maximum filling depth

16mm

16mm

16mm

Tablet thickness range

0.5~9mm

Maximum tablet diameter

Ф25mm

Ф16mm

Ф13mm

Ф10mm

Maximum abnormal axis size

<25mm

<19mm

<16mm

<11mm

Die diameter

Ф38.10mm

Ф30.16mm

Ф24.00mm

Ф19.00mm

Plunger diameter

Ф25.35mm

Ф19.00mm

Ф19.00mm

Ф16.00mm

Plunger length

133.60mm

Working noise

≤70dB

Total power

7.5KW/380V, 50Hz,

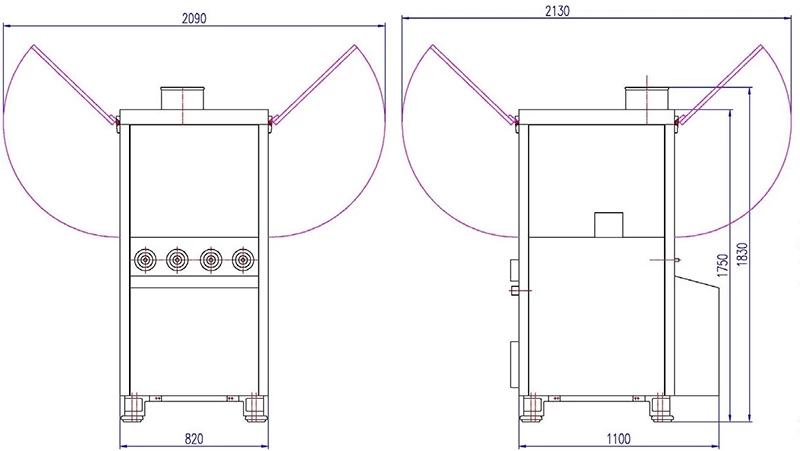

Boundary dimension of equipment

820×1100×1750 mm

Net weight of equipment

1450kg

The maximum production refers to the maximum production realized under the conditions of round tablets, minimum tablet diameter and maximum rotating speed. The production is influenced by tablet diameter and tablet type.