Usage

HLT series pillar bin blender is extensively used for mixing dry powder with dry powder or dry powder with grain in the process of diversified solid preparation production in the pharmaceutical industry. This mixer can be equipped with bin of various specifications, It is suitable for mixing pharmaceuticals of multiple varieties and different batches according to the technological requirements in large and medium-sized pharmaceutical enterprises, so it can achieve multiple purposes in one machine.

Features

1. It is a high-tech product which integrates machinery, electronics and hydraulics into one body. It employs mechanical(hydraulic) lifting and driving, and PLC control, which is easy to operate and convenient to adjust technological parameters.

2. The control system is highly sensitive, and the whole machine is compact in structure,stable and reliable in running.

3. A single machine can be equipped with bins of various specifications. I The material remains in the bin after mixing . which will be dismounted from the rotating arm and shifted directly to the next procedure, thus greatly improving the utilization efficiency of the mixer and also avoiding cross contamination of materials.The machine completely accords with GMP requirement.

4. The mixing barrel can be used as a batching barrel in the upstream procedure and also as a charging bin in the downstream procedure(compressing and filing of tablets).

5. The evenness of mixing reaches above99%, the volume charge coefficient reaches0.80. Both inner and outer surfaces of the barrel are clean and smooth without dead corner.

6. After mixing each batch of pharmaceuticals,the empty bin is sent to a special cleaning room for cleaning so that to keep the workshop clean.

Working Principle

When running the machine, push the mixing bin into rotary arm and tighten the nuts, then start the control system and lift the bin to the mixing height='auto' rea. Then, the control system starts mixing automatically according to the setting time and rotation speed, etc. When finish mixing, the material fixed in a horizontal position and the bin downwards to the ground automatically.After that, the whole machine stop and print process data. Finally, unfasten the locking nuts of rotary arm and move the bin out, and transfer it to the next process. As the symmetrical axes of bin and the rotating center line of rotating arm form an included angle, materials with different constituents are strenuously rolling over in the closed bin and producing high shear to achieve the best effect of mixing.

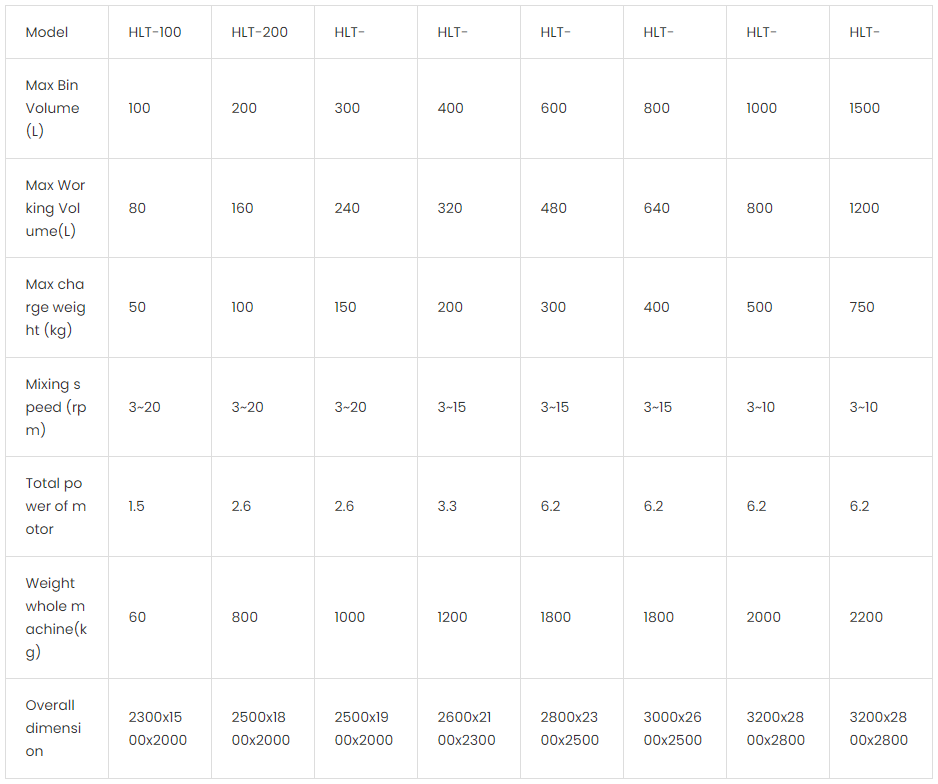

Specifications