Usage

The GLX-50 universal full automatic dry granulator (Roller compactor)is the most advanced home-made one in the world, which is designed and developed on the basis of GMP concepts and characteristics of Chinese patent medicines and biochemical medicines.

Roller compactor widely applied for granulation in such industries as pharmacy, food and chemical engineering, which is especially applicable for granulation of materials vulnerable to being decomposed and ineffective or agglomerated when contacting wet and heat.

The grains it produces are directly used for granule packets, tablets and filled capsules.

Feature

1. Negative pressure airflow automatic feeding enables powder to be conveyed inside closed pipeline which stops dust's flying.

2. Reverse rotation of constant torque German servo motor driven twin-screw achieves high-efficiency and precision feeding which assures quality of sheets.

3. High-precision pneumatically-controlled eccentric roller adjusts dimension of sheet thickness which ensures running parallelism of two pressing wheels and enables sheet thickness and sheet hardness to be even.

4. Effect of W-type curved surface grains- arranging mode is excellent and fine powder is less.

5. Fine powder of airflow vibrating sieving device is directly sucked away by vacuum and rate of finished fine powder is controlled at 5% below.

6.The overall easily removable design, taking 20 minutes only, facilitates cleaning and makes cleaning easily acceptable

7. Before the work is finished, self-configured negative pressure air pump pre-cleans machine's working chamber and sucks away residual medicinal powders inside materials bucket, charging barrel, periphery of pressing wheel, whole grain and sieving.

8. High-end configuration of PLC and 10" touch screen precisely controls feeding, pressure, force moment, speed, formula, sheet thickness, amount of powder supply and sieving, etc, and will run data display and can also upload server or printout by IDS.

9. Helical feeding mode has synthesized advantages of vertical and flat feeding and meanwhile dodged disadvantages of vertical and flat feeding.

10. The unique pneumatic vibration screening system can coordinate the star-type valve to keep discharging materials and recycling the thin powder. It can control the thin powder rate of the finished products below 5%.

11.The revolving electric cabinet is compact in construction. It is easy for the user to maintain it.

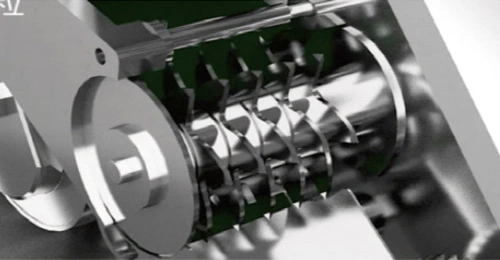

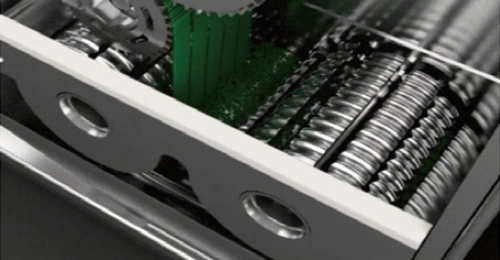

12.The full closed granule- making box can coordinate the radial up and down pressing pulleys and the axial space, so it can meet all the requirements for pressing different kinds of powder tablets. It is composed of W-type screen, gear-type granule organizing pulley, wave-type screening pulleys. So the granules are well organized, with lower rate of thin powder.

13.It can automatically lift the feeder to coordinate the star-type and the screw rod to continue feeding materials to the pressing pulley to equal the thickness and hardness of the tablets.3. Helical feeding mode has synthesized advantages of vertical and flat feeding and meanwhile dodged disadvantages of vertical and flat feeding.

14. The unique pneumatic vibration screening system can coordinate the star-type valve to keep discharging materials and recycling the thin powder. It can control the thin powder rate of the finished products below 5%.

15.The revolving electric cabinet is compact in construction. It is easy for the user to maintain it.

16.The full closed granule- making box can coordinate the radial up and down pressing pulleys and the axial space, so it can meet all the requirements for pressing different kinds of powder tablets. It is composed of W-type screen, gear-type granule organizing pulley, wave-type screening pulleys. So the granules are well organized, with lower rate of thin powder.

17.It can automatically lift the feeder to coordinate the star-type and the screw rod to continue feeding materials to the pressing pulley to equal the thickness and hardness of the tablets.

Application

Machine Details Packaging

Machine Detai

Grain specification

Model

GLX-50

GLX-300

Tabletting capacity

kg/h

3~50

50-400

Granlating capacity

kg/h

3~35

50~250

Pinch roller rotation speed

r.p.m

3~30

3~34

Pinch roller rotation speed

r.p.m

20~200

5~300

Straightening rotation speed

r.p.m

5~130

50~150

Φmm

10~80/2~0.18

Pinch roller pressure

KN

98

4300

Air source pressure

Mpa

0.4~0.7

0.4~0.7

Air consumption

m³/min

0.12

0.5

Main machine power

Kw

8

19.5

Auxiliary machine power

Kw

3

5

Main machine weight

Kg

800

2500

Overall dimension

L x W x H mm

1000 x 1000 x 2100

1000 x 1700 x 2500